At HeatSync, our team of world-class thermal engineers has tackled some of the most demanding thermal challenges across leading industries. Our expertise spans all aspects of thermal solutions for electronics—design, simulation, testing, troubleshooting, and optimization. Our aim is to enhance your product’s performance, safety, comfort, and efficiency.

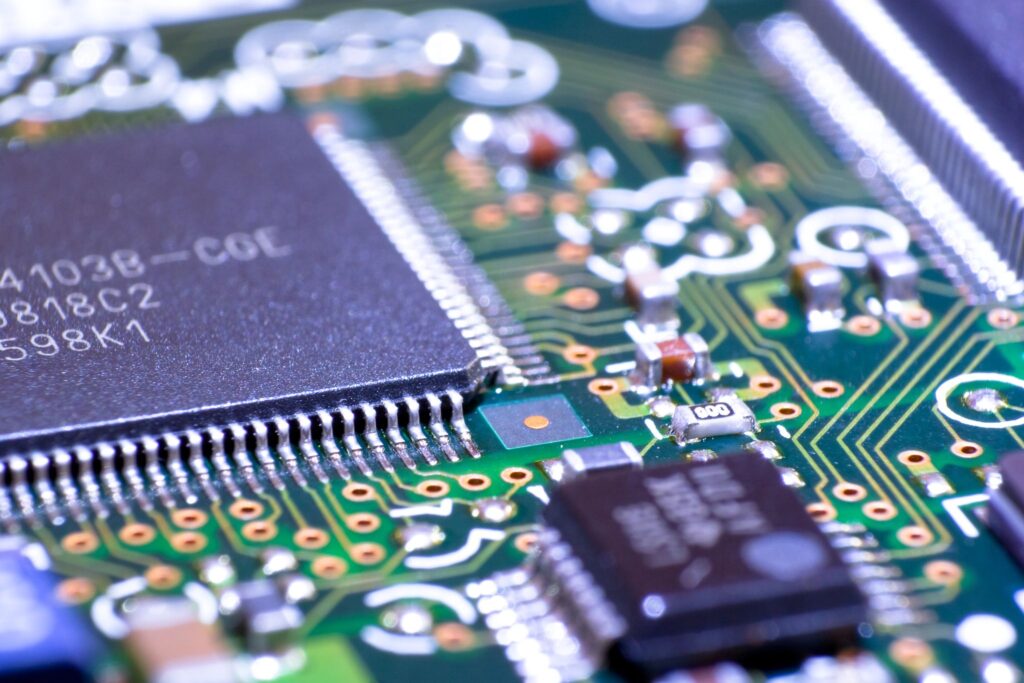

At HeatSync, we excel in the design and optimization of thermal architectures for electronics, using advanced knowledge of components like fans, heat pipes, vapor chambers, thermal interface materials (TIMs), cold plates, heat spreaders, and heatsinks. Whether your system needs air-cooled or liquid-cooled solutions for indoor or outdoor applications, we ensure optimal thermal performance tailored to your needs.

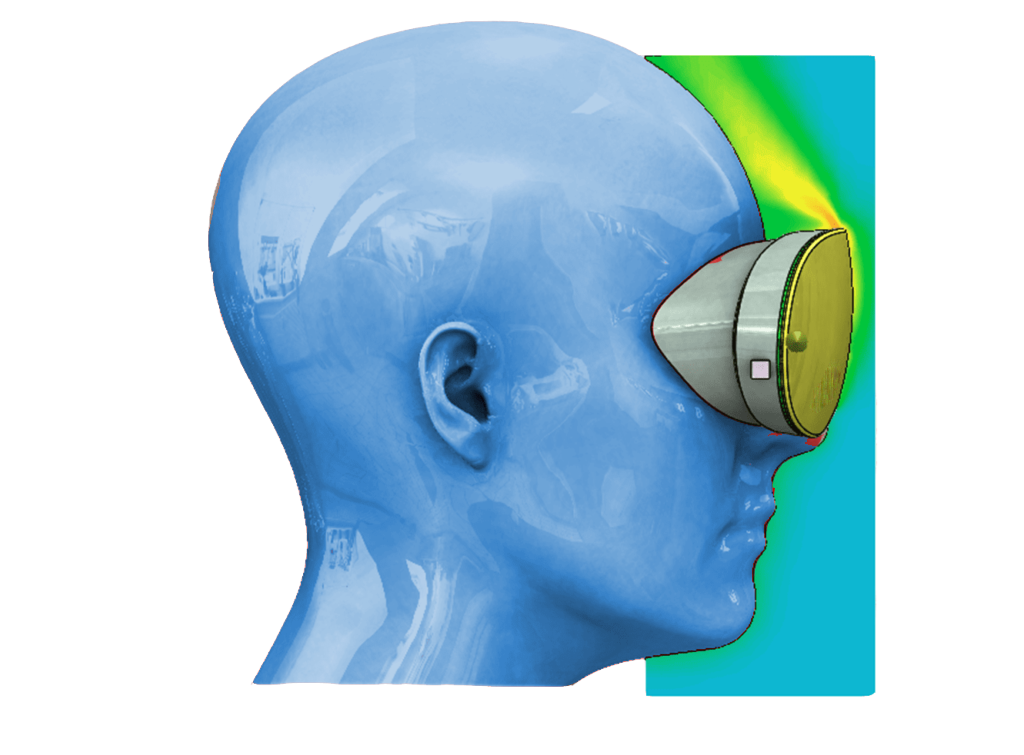

With experience across consumer electronics, data centers, and energy storage systems, our engineers enhance wearable comfort, optimize transient thermal performance for portals, improve fan-sink heat dissipation, and develop innovative cooling methods for tablets and laptops, achieving strict temperature control with minimal noise. Our solutions reduce thermal stress, extend device lifespan, and maintain high performance in diverse environments, delivering reliable and efficient cooling that meets the demands of high-performance electronics and ensures user satisfaction.

We provide comprehensive thermal testing services designed to ensure optimal performance and reliability for your systems. We create Design of Experiments (DoE) and custom test setups tailored to each project, enabling precise testing and analysis. Our advanced thermal testing capabilities include:

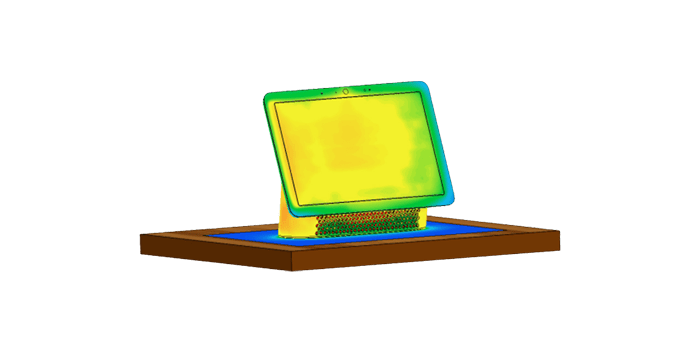

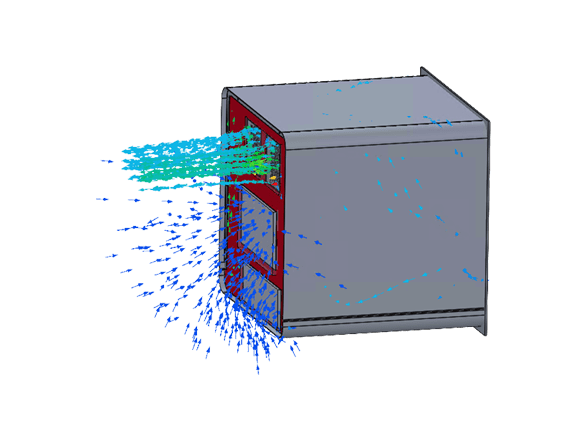

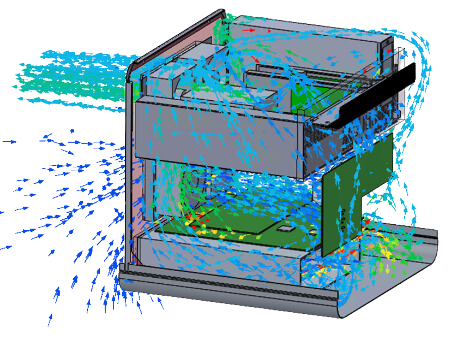

We specialize in airflow optimization to enhance energy efficiency, maintain temperature stability, minimize noise levels, and boost system reliability. Our redundant designs ensure that systems perform effectively even under unexpected conditions or environmental stressors.

Our expertise covers the selection and strategic placement of fans and blowers to achieve optimal airflow performance. With an advanced understanding of how air-moving devices respond to varying temperatures, pressures, and altitudes, we create airflow solutions that are reliable and efficient across all operating conditions. This knowledge enables us to design high-efficiency systems that operate at peak performance even in challenging environments.

In applications such as wearable devices, skin temperature monitoring is essential for ensuring user comfort and safety, optimizing device performance, and providing accurate health-related data. However, physical temperature sensors present challenges, including limited placement options and variability in hot spot locations.

To overcome these limitations, our engineers implement virtual temperature sensors that dynamically estimate temperature readings, providing reliable monitoring without the constraints of physical sensors. These solutions ensure continuous, precise tracking of critical temperatures for enhanced safety and performance.

At HeatSync, we leverage Artificial Intelligence (AI), Machine Learning (ML), ROM, Digital Twins and 1D system-level analysis to optimize complex thermal solutions. These tools allow us to account for interactions among multiple components and the dynamic changes in environmental or operating parameters, ensuring peak performance, safety, energy efficiency, durability and reliability.

Our expertise empowers clients with faster, more accurate analysis and decision-making. With advanced AI and simulation tools, we can proactively detect and resolve potential issues before they affect performance. Whether maintaining the reliability of battery systems or enhancing data center cooling, HeatSync delivers intelligent, adaptive solutions to meet the most complex challenges efficiently.

We design and optimize liquid cooling systems for applications like GPUs, servers, and battery packs. Our expertise spans microchannel cold plates, large-scale cold plates, and single- or two-phase immersion cooling systems, ensuring high-performance thermal management tailored to the specific needs of each system.

We excel in all aspects of liquid cooling design, including the cold plate assembly, construction of thermal test vehicles, prototyping, and testing. Our hands-on experience enables us to create reliable and efficient cooling solutions that not only meet but exceed performance and reliability expectations.

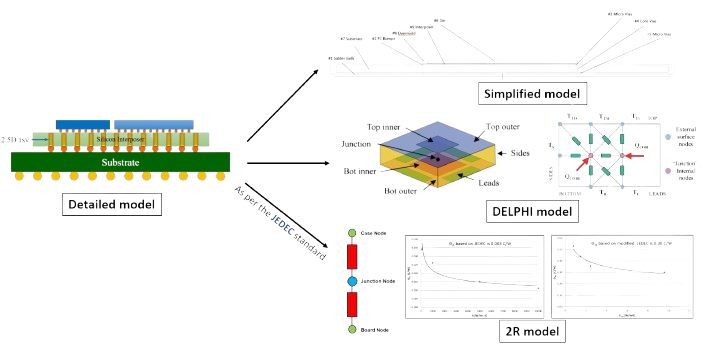

Our team develops detailed thermal models like Delphi and 2R models to streamline the design process without sacrificing accuracy. These models offer precise thermal predictions, improving performance from component-level to system-level designs.

Our expertise in creating and applying these models ensures that our clients achieve precise thermal predictions, efficient simulations, and faster development cycles, optimizing performance from component-level to system-level designs.

At HeatSync, we conduct comprehensive reliability studies to predict and mitigate potential failures in electronic components, ensuring long-term performance and durability. Our expertise includes: