Knowledge Center

Brochures

Our brochures highlight HeatSync’s capabilities in thermal design, simulation, testing, and optimization across various industries. They provide valuable insights into how our team tackles complex thermal challenges in electronics, battery energy storage, EVs, data centers, and beyond. These brochures can be downloaded for a deeper understanding of HeatSync’s solutions and expertise.

Thermal Management of Electronics

Discover how HeatSync’s expertise in thermal management optimizes cooling solutions for electronics from chip-level to system-level. Our tailored consulting services enhance energy efficiency, reliability, and safety in applications across consumer electronics, data centers, telecommunications, and beyond.

Thermal Management of Batteries

Explore HeatSync’s comprehensive thermal solutions for Li-ion battery systems, from cell-level to pack-level. Our consulting services focus on maximizing performance, lifespan, and safety in battery thermal management for applications such as electric vehicles, energy storage systems, and consumer electronics.

Thermal Architecture Design for Smart Glasses

HeatSync was tasked with designing a thermal management solution for smart glasses generating 13.5 W of heat. Designed for indoor use at 27°C, the project required addressing compact form factor constraints, user comfort,and safety standards. Using our systematicdesign approach, we delivered a comprehensive solution ensuring optimal performance and reliability.

Optimizing 2.5D IC Package Design for Reliability

HeatSync was approached by a client to optimize the design of a 2.5D IC package, addressing key reliability challenges posed by thermal cycling, including solder joint fatigue, delamination, and warpage. The goal was to enhance durability while improving both thermal and mechanical performance. Using advanced simulation techniques, HeatSync delivered an optimized package design that met the client’s reliability and performance requirements.

Digital Twin for Predictive Thermal Management of EV Battery Packs

HeatSync developed a Digital Twin model for a 90 kWh lithium-ion (Li-ion) battery pack to optimize thermal management, performance, and safety in electric vehicles (EVs). This advanced model enabled real-time monitoring, predictive maintenance, and system-level optimization, allowing engineers to simulate and refine battery behavior under diverse operating conditions. By integrating live sensor data and reduced-order modeling (ROM), HeatSync’s Digital Twin solution provided accurate temperature predictions while significantly reducing computational costs.

Advanced Direct-to-Chip Liquid Cooling Implementation in High-Density Data Centers

A leading cloud service provider aimed to retrofit its 4 MW data center to support direct-to-chip liquid cooling at 20 kW per rack. The objective was to enhance cooling efficiency, reduce energy consumption, and improve server reliability. HeatSync was engaged to develop a comprehensive solution encompassing detailed system-level modeling, AI-driven optimization, and performance validation.

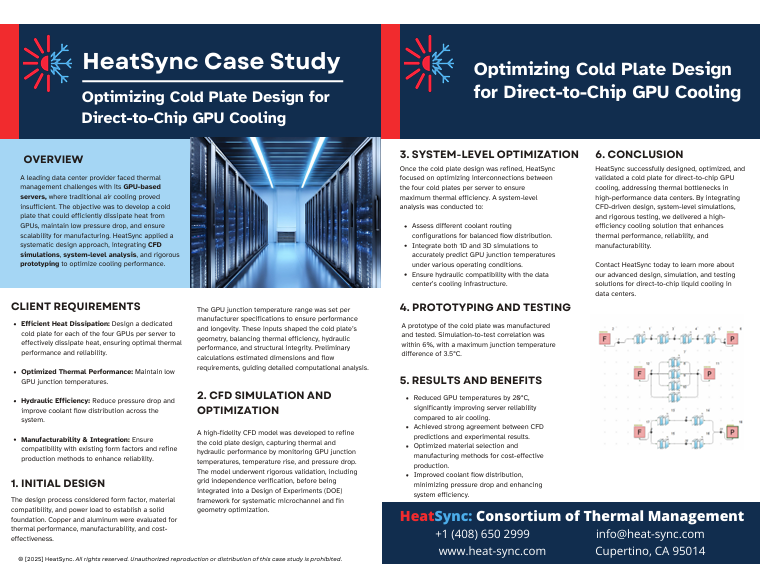

Optimizing Cold Plate Design for Direct-to-Chip GPU Cooling

A leading data center provider faced thermal management challenges with its GPU-based servers, where traditional air cooling proved insufficient. The objective was to develop a cold plate that could efficiently dissipate heat from GPUs, maintain low pressure drop, and ensure scalability for manufacturing. HeatSync applied a systematic design approach, integrating CFD simulations, system-level analysis, and rigorous prototyping to optimize cooling performance.

Thermal Management for an EV Battery Pack

HeatSync designed and optimized a thermal management solution for a 90 kWh Li-ion EV battery pack to maintain optimal temperature, prevent thermal runaway, and ensure long-term reliability. Utilizing advanced simulations, testing, and real-time Digital Twin models, the solution enhances battery performance, safety, efficiency, and lifespan under diverse conditions.

Thermal Cycle Testing for Defect Detection and Lifetime Estimation of Customer Package

HeatSync was approached by a client seeking to evaluate the reliability of their custom electronic package by detecting defects, such as solder joint failures, and estimating the lifetime of the package under operational conditions. HeatSync utilized advanced thermal cycling techniques and industry standard methodologies to conduct comprehensive testing tailored to the client’s needs.